In the precise realm of long-range rifle shooting, particularly with the versatile and increasingly popular 5.56mm Creedmoor cartridge, the quest for accurate and reliable reload data stands as a cornerstone of responsible and effective ammunition handloading. The journey towards mastering this aspect of reloading not only involves understanding complex ballistic principles but also requires navigating a landscape filled with varying sources, safety considerations, and technological innovations. Recognizing the significance of trusted data in achieving optimal firearm performance and safety, this comprehensive guide explores the historical development, sources, and methodological approaches to sourcing and validating 5 Creedmoor reload data. We aim to illuminate the intricate pathways that allow enthusiasts and professional reloaders to consistently produce accurate, safe, and high-performance ammunition tailored to their specific rifles and shooting conditions.

Introduction to 5 Creedmoor Reload Data: Safeguarding Precision and Safety

The 5 Creedmoor cartridge, introduced in 2007 by Hornady, revolutionized long-range shooting with its high ballistic coefficient, flat trajectory, and relatively low recoil. Its widespread adoption in competitive shooting, hunting, and tactical applications underscores the critical need for reliable reload data. Reloading, when executed with precision, allows shooters to tailor ammunition to their firearm’s unique characteristics, environmental conditions, and desired performance metrics. However, the inherent risks associated with incorrect load data—potentially leading to catastrophic firearm failures or inconsistent accuracy—highlight the imperative for sourcing data from authoritative channels and adhering to best practices in load development.

Foundations of Accurate and Reliable Reload Data for 5 Creedmoor

Accurate reload data encompasses the complete set of specifications—powder types, charges, bullet weights, seatings, and primer choices—tailored to produce predictable and safe ballistic outputs. Reliability in data refers to its consistency across different batches and user experiences, ensuring that practitioners can reproduce results with confidence. Achieving this dual goal demands an understanding of several foundational principles:

- Source credibility: Data must originate from reputable and industry-recognized resources backed by empirical testing and peer validation.

- Methodological rigor: Proper context, such as firearm condition, barrel twist rate, and environmental parameters, must be specified, allowing for precise adaptation.

- Incremental development: A cautious approach involves starting at the minimum recommended charge and progressing gradually, observing pressure signs and accuracy before advancing.

- Data validation and cross-reference: Comparing multiple trusted sources enhances confidence and helps identify anomalies or updates in load recommendations.

High-quality load data combines technical accuracy with comprehensive safety margins, established through standard industry testing, thus embodying the principles of responsible reloading.

Key Sources of Trusted 5 Creedmoor Reload Data

For reloaders seeking reliable data, several industry-standard sources serve as primary repositories of verified information. Leveraging these sources ensures access to empirically tested and peer-reviewed specifications.

Official Load Data from Powder Manufacturers

Major powder producers such as Hodgdon, IMR, Nitrochemie, and Alliant provide detailed load data explicitly tailored to the 5 Creedmoor cartridge. These datasets are developed through extensive internal testing, often involving multiple firearm platforms, to establish safe charge ranges. For instance, Hodgdon’s online powder database consistently updates its load recommendations, reflecting ongoing research and user feedback, making it a cornerstone resource for responsible reloaders.

| Relevant Category | Substantive Data |

|---|---|

| Hodgdon Hodgdon H4350 | Charges range from 39.0 to 43.0 grains for 140-grain bullets, with pressure and velocity data validated through SAAMI standards. |

| IMR 4451 | Recommended loads for 130-150 grain projectiles starting at 41.0 grains, with maxes not exceeding 44.0 grains. |

Reputable Reloading Manuals and Guides

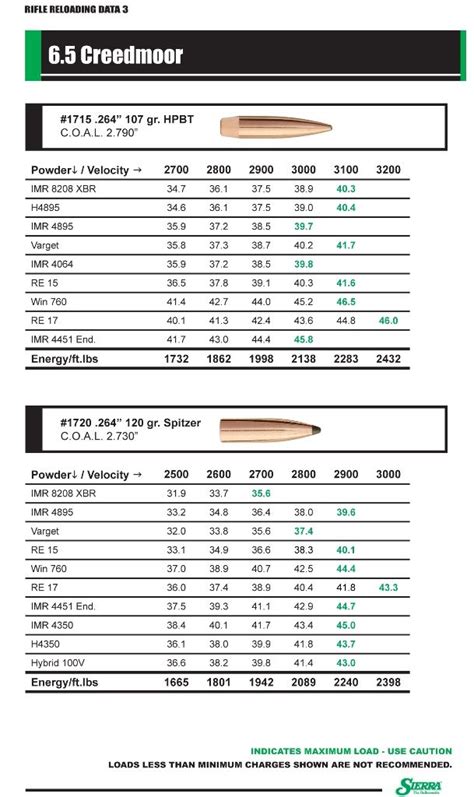

Comprehensive manuals from Hodgdon Reloading Data, Nosler Reloading Guide, and Sierra Bullets provide detailed load data backed by extensive testing and practical experience. Recent editions incorporate updates from real-world user findings and scientific pressure testing, offering a nuanced perspective that aligns with current safety standards. For example, Sierra’s Reloading Manual 7th Edition includes specific 5 Creedmoor load recipes with detailed notes on bullet seating depths and velocity expectations.

Research Papers and Technical Publications

Advances in internal ballistics research, published through the Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI) and independent ballistic labs, offer peer-reviewed data that often refine or calibrate existing load recommendations. Access to such publications through industry subscriptions or academic libraries ensures that reloading practices remain evidence-based and current.

| Relevant Category | Substantive Data |

|---|---|

| SAAMI Pressure Standards | Maximum average pressure for 5 Creedmoor set at 62,000 psi, guiding safe load development. |

| Technical Journals | Studies indicate that specific powders like H4350 produce consistent velocities within a 1% margin at recommended charges. |

Practical Methodologies for Validating and Customizing Load Data

While authoritative sources provide essential benchmarks, individual firearm characteristics and environmental conditions often necessitate personalized validation. The practice of load development should follow a systematic process:

- Start low and go slow: Begin with the minimum load recommended for your bullet weight and powder type, ensuring safe functioning.

- Incremental increases: Increase charges in small steps, typically 0.2 to 0.3 grains, while observing for signs of pressure escalation such as flattened primers or sticky extraction.

- Record-keeping: Maintain detailed logs including velocities, accuracy data, and firearm conditions to track performance across different loads.

- Use of chronographs and precision scopes: Collect empirical data on velocities and group sizes to optimize load selection.

- Pressure testing if available: Employ strain gauges or pressure sensors for advanced load validation, particularly when pushing towards max loads.

This disciplined approach ensures safety, optimal performance, and scientific rigor, aligning with ethical reloading practices that prioritize shooter safety and firearm longevity.

Limitations and Risks in Relying Solely on Published Data

Despite the value of reputable sources, reloaders must recognize the limitations inherent in generalized data. Variability in firearm condition, chamber dimensions, barrel length, and even primer batch can influence chamber pressures and accuracy outcomes. Over-reliance on published data without local validation may inadvertently lead to unsafe conditions. Moreover, advances in propellant chemistry and new powder formulations necessitate continuous re-evaluation of traditional guidelines.

It’s also noteworthy that proprietary or unpublished data from individual reloaders, while lacking peer review, can sometimes reveal practical insights into specific load tweaks, provided they are approached with caution and thorough testing.

Emerging Technologies and Forward-looking Trends in Load Data Validation

Innovations such as pressure measurement devices, high-speed cameras, and 3D ballistic modeling software are transforming how enthusiasts and experts develop load data. For instance, integrated strain gauges allow real-time pressure monitoring, removing guesswork from load development. Simulations utilizing advanced ballistics software can predict trajectory and pressure outcomes, permitting pre-emptive adjustments before live testing.

Final Considerations for the Responsible Reloading of 5 Creedmoor

In sum, sourcing and validating accurate and reliable 5 Creedmoor reload data is a multifaceted process that balances authoritative references, methodical experimentation, and technological innovation. Responsible reloaders treat published data as a starting point, tailoring and refining loads through meticulous testing and observation. Adhering to safety standards, understanding firearm-specific nuances, and leveraging industry resources collectively ensure the production of high-quality ammunition that meets the dual imperatives of performance and safety.

The pursuit of perfection in reloading is an ongoing journey—marked by continuous learning, adaptation, and rigorous scientific approach. By integrating empirical data, expert insights, and emerging technologies, enthusiasts and professionals can confidently navigate the complexities of 5 Creedmoor reload data, ultimately achieving consistency, safety, and excellence in their shooting endeavors.

How do I determine the safe maximum load for my 5 Creedmoor rifle?

+To determine the safe maximum load, start with published maximums from reputable sources such as Hodgdon or Sierra, then load incrementally while closely monitoring primer, case, and firearm signs of pressure. Using a chronograph and pressure testing equipment, if available, can help refine your load within safety margins established by SAAMI standards.

Can I rely solely on online load data from forums or unverified sources?

+While online forums can offer practical insights, they should not substitute data from official manuals or manufacturer specifications. Always cross-reference information and validate through cautious testing within recommended safety margins to avoid risks associated with unverified data.

What environmental factors should I consider when developing reload data for 5 Creedmoor?

+Temperature, humidity, altitude, and atmospheric pressure all influence ballistic performance. Adjusting load data based on these factors, such as increasing charges slightly in colder conditions or at higher elevations, can enhance consistency and accuracy. Nonetheless, the foundation remains in empirical validation and adherence to safety guidelines.

How often should I update my load data or re-verify my loads?

+Periodic re-verification is recommended, especially after changing components like primers, powder lots, or barrel condition. At minimum, re-evaluate each new batch of components or after significant firearm maintenance, ensuring that your load remains within safe and optimal parameters.